Kevin Murphy: Welcome back to season two of What Matters Most, Sands Capital’s podcast series in which we explore some of the trends in businesses that are propelling the pace of global innovation and changing the way we live and work today and into the future.

Today we’re talking with Daniel Pilling, a technology analyst here at Sands Capital and an expert in all things semiconductors. Semiconductors or microprocessors are in seemingly everything these days. If it has a plug, an on-off button, or a battery, it most likely has at least one microchip.

While these items are ubiquitous in everyday life, running cell phones, driving our cars, making our coffee, and answering our questions with increasing sophistication, few of us really understand the history, complexity, and key players in this increasingly important, highly dynamic industry.

We’ll start the conversation with a 30,000-foot look at the industry in general. Then we’ll dig into how, over the last 30 years, Sands Capital has refined its approach to investing in this sector by focusing on the chokepoints in the manufacturing process in order to uncover the companies we think are best poised to benefit from this increasing demand for compute [computing power].

With this history and focus as the backdrop, we’ll dive into one company in particular that we think has the potential to be a key beneficiary of what we believe will be a decadeslong period of outsized growth in the semiconductor manufacturing industry. The company we’re discussing today is Entegris, a less-known but critically important “arms dealer” to the global semiconductor industry and, we think, an excellent example of what matters most when investing for long-term success in this dynamic growth industry. Along the way, we’ll likely touch on GPUs [graphics processing units], AI [artificial intelligence], and NVIDIA as key enablers of this industry growth, but we’ll also focus on how Entegris is keeping up with this increasingly complex semiconductor thesis.

So Daniel, let me start with the history. Take us through the big picture here. We could spend hours on this fascinating history. From my understanding, it started really back in the 1940s as a way for the military to more accurately target bombs dropped on the battlefield, that sort of thing, but it was done through vacuum tubes, which are highly inefficient and tend to break down pretty frequently. That sort of thing. So, you had folks like William Shockley, who discovered the properties of semiconducting materials, and from there the industry grew. So tell us how it grew. Give us kind of an idea of what it looked like then and what it looks like today—and maybe some of the steps involved in creating the microprocessors that we use a lot today.

Daniel Pilling: Yes. Hi Kevin. Thank you for the great questions. So maybe I’ll give you a bit of a different spin on that question, if I may.

Kevin Murphy: Please.

Daniel Pilling: And I would argue the key driving force here is two things. First of all, it turns out humanity has a lot of need for compute. And there’s a great academic paper that talks about how the need for compute for all of us humans grows at about 50% annually. I can take this from the 1940s to now. The second most important thing is, I suppose, Moore’s Law [the observation that the number of transistors on every integrated circuit doubles about every two years]. And then let’s combine those two to give a bit of a historical perspective.

So maybe if you look at the last 30, 40-ish years, you had a few product cycles—big product cycles. One was the mainframe. Another was the PC, then the smartphone, and then artificial intelligence. And all of those are effectively an outgrowth of this need for compute. So our lives have changed significantly, right? We all have a PC. We all have a smartphone. We all have a cloud footprint. And we’re all going to have an AI footprint. And then the way that this was actually enabled points back toward the history that you quote. So in the early 1980s, 1990s, and 2000s, you had much bigger transistor sizes, which meant that, in a finite footprint, you could only do a finite amount of compute, which was driven by the numbers of transistors in that footprint.

Now, Moore’s Law enabled us to shrink—or continue to shrink—these transistors over time, which then again enabled us to put more logic and more compute effectively in the same footprint. I think the best example of that is actually the smartphone, right? Initially you had Nokia phones. They were fairly big, ginormous, and the coolest game you could play was Snake, which was a lot of fun, right? But it’s nothing compared to what you can do now. Today, on an iPhone, you can play literally any game. And the iPhone has a higher compute intensity, ability, than any mainframe in the seventies and eighties.

So I think to me the history of compute is twofold. One, there’s an insatiable need for compute. So as I mentioned, it grows about 50% each year, which is obviously a ballpark number. We don’t know the precise number. And then, two, all of this is enabled by Moore’s Law and this ability to keep on shrinking the transistors, which allows us to put more compute in the same amount of space. I suppose the best example, I said, is the smartphone; it turns out the iPhone built the biggest market cap in the world [for Apple] on that exact trend.

Kevin Murphy: So, give us a real world example, if you can, in terms of when you say shrinking the circuitry on the chip following Moore’s Law, where was it then and where is it today? And, if at all possible, give us a frame of reference because I think it’s hard to think in nanometers.

Daniel Pilling: Yeah, yeah.

Kevin Murphy: What are we talking about? How small was it? How small is it today?

Daniel Pilling: So, I mean, if you think about vacuum tubes, I guess each vacuum tube was one transistor effectively, and they used to be ginormous. So you see these pictures from the 1940s and ’50s that some of the universities where they cart in all the stuff, and its like a giant room, and actually they can’t do so much compute with it And then today, the foundries of the world, they’re talking about five-, three-, and two-nanometer types of leading-edge chips. Now I actually Googled this in advance because when you look at this industry, you’re so used to this stuff, so actually, you don’t think about these things.

But it turns out a human hair is 80,000 nanometers. 80,000. So if we take what Taiwan Semiconductor is telling us as, OK, this is a five-nanometer transistor, and the comparisons are basically you could fit many, many, many, many thousands of these transistors into a human hair. Now, I should caution that the five-nanometer name is obviously a marketing term. The transistor itself is actually going to be bigger. But so, ballpark, that’s where you get to, right? So, the sizes we’re talking about here are many times smaller than a human hair.

Maybe lastly, another way of thinking about this. Take the latest chips from NVIDIA, for example. They have tens of billions of transistors within a small die, fairly small. So our ability to cram more transistors onto the same die has gone up by many, many, many thousands. And that enables things like NVIDIA and Apple, etc.

Kevin Murphy: That’s interesting. So I’m assuming that as the number of transistors on a chip goes up, the complexity of making these chips follows that same exponential growth. Is that a fair statement?

Daniel Pilling: I think that’s a fair statement, and we actually have some data on that. So there are a few things that are happening. Let’s first of all decide why are we shrinking in the first place? What’s the point of that? So the point is, for example, in the smartphone, there’s a finite space, right? We can’t carry bigger smartphones. If you shrink the transistors, you can put more into them, and that means you have more logic, and the phone can do much more stuff at the same time. That’s super valuable.

The same argument counts for the data center and all the NVIDIA AI chips; you have to shrink them. They become better in terms of using less electricity per compute. So you keep on shrinking them, and they can do more things, and ChatGPT pops up. So then you say, well, OK, how do we enable that? And the enabling part is … You’re right, it becomes incredibly complex. Now why is that? When you shrink a transistor, a transistor is basically just a one or a zero. And you show that state by either having an electrical charge or you don’t have an electrical charge.

Now, when you shrink the transistor, what happens is that there could be tunneling effects, there could be various effects that could mean that either it’s a zero or one, but it’s not supposed to be a zero or one, simply because you’re shrinking it so much. Now, in order to do that, you have to do so-called 3D architectures, right? Like better installations, funkier structures, yeah.

One transistor is called the FinFET, for example, which was introduced in 2010. Another is called gate-all-around, which is being introduced at the moment, which basically means that instead of having a planar transistor, imagine a city. It’s like some cities are not big enough, and maybe they don’t have any skyscrapers, but now you’re going to these skyscraper-ish architectures.

Now, if you want to build a skyscraper, it’s going to take you way longer to do that. You need more cement, more people, much more time, much more sophisticated materials. The exact same thing is happening here. If you want to construct these small but 3D architectures in the transistor, you’re going to need more chemicals, more filtration, more process steps. It’s going to become much more complicated, which means your yield will get lower. So you may have to produce more of them, and it’s literally like a rule of physics. Imagine you’re baking bread, and instead of 50 process steps to bake the bread, it takes you 500. Obviously, you’re going to bake much less bread, so you need to buy more ovens. The exact same thing is happening here.

Kevin Murphy: OK. That’s interesting. Before we discuss the specifics of Entegris, maybe give us a quick overview of the steps you mentioned. What are the general steps in the process from taking that wafer of silicon to the end product of a microchip?

Daniel Pilling: Yes. So, you start out with something called a silicon wafer, which is made out of silicon. And it’s basically like a big circle made out of silicon, and it’s raw, so there’s nothing on there. And then, I’d say there are three key steps. One is a lithography step, which is basically you transfer a pattern from a photomask, something that has the pattern of the chip that you want, and you transfer it onto a substrate via photolithography. And the company doing that on the leading edge is called ASML. They’re a monopoly; they’re the only company in the world that can do what they’re doing. That’s one step.

Now, once you have the pattern on the wafer, you need to be able to etch and deposit materials on it to show this pattern. So, basically, imagine you’re building a house. So first, you have a blueprint of the house, then you start building stuff, so you’re depositing cement, in this example. But actually, here you also have to take things away. So imagine you put the entire slab of cement and then you start chiseling out the features of the building. This is the position and etch. So you have three steps: you have lithography, which puts the pattern on; you have deposition, depositing materials; and then you have etch, which etches out some of these materials to create these 3D structures. And the nice thing is that all of those are going up. Because if you want to create these 3D structures, you’re going to have more so-called process steps, which means all of those are getting more intensive, and you need more equipment to do that.

Kevin Murphy: That’s helpful. I think that sets some context for people when we dig into the specifics that Entegris provides to the process. One other thing before we start down the path of talking specifically about the company, what are some of the main issues? I’ll note that people are well aware that semiconductor manufacturing is a highly cyclical industry, and cycles happen because of an imbalance between the supply and the demand sides. And you’ve described, I think, pretty well the increase in demand. It’s kind of lumpy. Big new things come along. You mentioned cellphones. You mentioned AI. AI’s kind of the new big demand driver right now. Maybe we can flip to the supply side.

What are some of the constraints to meeting that demand from time to time? Where are we today in that process? And then, I’ve thrown a lot of questions out there, but one other thing I’d like you to touch on: When you do any research into the global supply chain for semiconductors, you’ll find out that there’s a massive lack of supply chain diversification there. There are really only a few companies that can manufacture these things, and they’re located in some geopolitically challenged areas as well. So talk a little bit about the supply side here.

Daniel Pilling: Well put, Kevin, and great question. So, when I was in school, I really enjoyed biology, and I’ll tell you why. In biology, you have these rules—and in physics, too, actually—you have these rules of things, and they just happen, and you follow the rule.

Now, one rule that you, I think, can apply in investing—and it applies super well to the semiconductor world—is that when R&D [research and development] intensity goes up, at some point, you only have a few companies that can follow. Because if five companies do all that R&D together, they won’t be profitable. Now, I’m telling you this for a specific reason. If you look, for example, at ASML, ASML is the leading-edge supplier of lithography equipment; there’s only one ASML. Now, why did it shake out that way? You could have had two, right? The reason why it shook out that way is because it took 20 years of R&D to develop that, and you have a cyclical industry.

Imagine you had two companies doing that. Maybe both couldn’t survive the cyclicality, but one company can do the R&D intensity, and they can thrive through the cyclicality. And that same argument literally goes everywhere in semiconductors. And it’s quite unique. I haven’t seen this anywhere else.

I can make that same argument for the vacuum valves that—believe it or not—create the vacuum within the machines. I can make a similar argument for chemicals and filters from Entegris. I can make the same argument for etch equipment from Lam Research, etc., etc., etc. So this is a naturally occurring phenomenon in this industry where only one, two, or three companies are able to follow the significant R&D intensity. So you naturally have a very consolidated supply chain.

What happens then? You have multiple layers here. You have the semi equipment layer—the ASMLs of the world—and they’re all very oligopolistic or monopolistic in what they do. You have the foundry layer, the Taiwan Semis [Taiwan Semiconductor] of the world.

And again, the same argument counts. You can’t have two Taiwan Semis of the world because it’s so R&D intensive. And then on top of that you have chip designers, and they’re a bit different.

But then, to be precise on your question, so when you have a significant demand shock, you have to have all of these oligopolies and monopolies move at the same speed, which is very hard. Because ASML, for example, is built on top of hundreds little of suppliers that do like, one widget, and they’re the only one in the world doing that, on top of that. It’s very hard for the supply chain to move altogether. But on the flip side, there’s also no other way of organizing this industry, right?

You could say, well, why don’t we have a second ASML? Well, because it took 20 years to develop. You can’t just do that. Why don’t we have a second Taiwan Semi? Because you need to have some big percentage of the—EUV [extreme ultraviolet] machinery to create the recipes that they’re doing to do what they’re doing. So it’s a bit of a blessing and a curse effectively, right? So you have these monopolies, but when big demand comes, you struggle to meet it. And then, obviously, the geopolitical positioning of it all is interesting too, and it seems to have happened that way. I guess there is a process of Taiwan Semi to create a production capacity in the U.S., Europe, and Japan.

But again, in my humble opinion, this is a fairly small part of the total capacity. So for now, if you want to have leading-edge chips, Taiwan is the place to go, and it’ll probably stay that way for a while.

Kevin Murphy: So that’s interesting. Let’s dive into Entegris then specifically. Daniel, walk us through how you came across Entegris,

Daniel Pilling: Yea, I’d say Entegris is a bit of a unique company to find. Because if you look at it from a sell-side perspective, it’s a chemical company and a filtration company that sells into the semiconductor space. So it tends to be covered by chemical analysts, but actually what really drives the business is semiconductors. But semiconductor analysts don’t know that company. So it’s sort of within two circles of expertise, and it tends to fall into the chemical bucket rather than the semiconductor bucket. Now I was fortunate. I got introduced to this company about 10 years ago by one of their larger investors.

So I’ve been tracking this company since both getting to know the CEO Bertrand [Loy], and we met him at various industry conferences also. So I feel like we know him quite well and can judge him quite well. And then at Sands Capital, this fell, neatly, in my opinion, in terms of into our criteria, both from, in the first five criteria, from the business quality, the growth, and the moat perspective, but also in terms of the valuation perspective.

And I would argue both of those are less appreciated by the market, mainly because it, again, falls into different parts of the coverage zone. The average semiconductor analyst is not a chemical analyst, and the average chemical analyst is not a semiconductor analyst. So I think that provides an opportunity, both in terms of the first five criteria – not many people know about the quality of this business and the growth duration – but that also percolates down into the valuation part of the criteria. It’s just not valued, at least in my opinion, how it should be. Yes, so hopefully, that explains a little bit of the history and how we found it.

Kevin Murphy: That makes sense. What are they supplying to the industry? Can you kind of describe that a little bit

Daniel Pilling: Entegris is actually a very unique company in this industry. Maybe I’ll start there. So most suppliers to the semiconductor manufacturing process are so-called “equipment players.” So they will manufacture a piece of equipment, and they sell it to you, and that’s called semiconductor capex [capital expenditures].

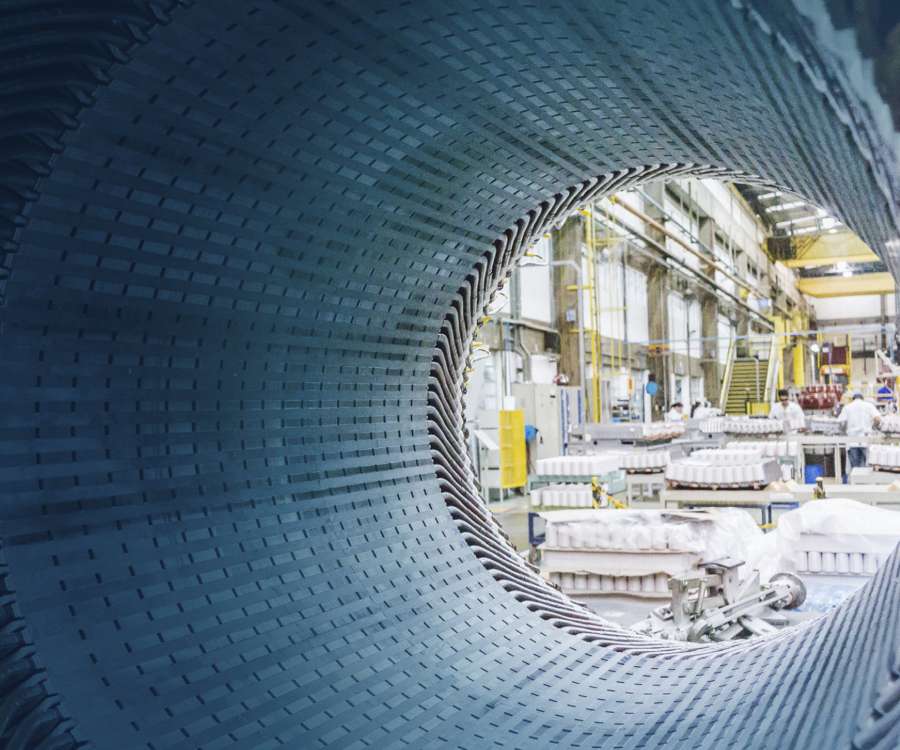

Now, Entegris is a bit of a different company. They’re mainly a consumables business. So if I manufacture a chip, I need a few things. I need chemicals. So as we discussed, there’s an etching and a deposition process, which requires chemicals. If I want to deposit something on the wafer, it’s probably some sort of gas or some sort of chemical I’m depositing on it. If I want to etch something out, I’m again going to use some sort of chemical or gas or something like that to do that. So you need chemicals, basically. The second thing you’re going to do is you need filters. Both during the manufacturing of the semiconductors, but also before, we need to filter these chemicals because, as we discussed in the beginning, these transistors are tiny.

So if you want to do this in a high-yielding fashion, you’re going to need very, very, very pure chemicals—unlike any other industry, probably. So in order to do that, you need to filter them. So Entegris does both. They filter the chemicals, and they provide the chemicals. They also do a third thing, which is actually the smallest part of their business. They have these wafer-handling equipment pieces, which basically enable you to put the wafer inside and send it around the fab [fabrication plant]. They’re also called FOUPS [front opening unified pods]. But that’s a fairly small part of their business, so it’s like maybe less than 10% of the EBIT [earnings before interest, taxes]. The bulk of this business is basically chemicals and filters. And you require those all the time because you keep on consuming them when you manufacture these chips.

Kevin Murphy: Great. That’s a good answer. I was reading one of your notes from one of the early notes on the business, and you used the term “one throat to choke.” What did you mean by that? Explain the idea behind that.

Daniel Pilling: Well, it’s a cool term. Basically, when you manufacture a semiconductor or when you manufacture basically anything, there are a few things you need to do. First of all, you have to find a supplier that can do what you’re asking them to do. Secondly, you have to approve that supplier. You have to say, well, I trust the supplier, and they have a vested interest in making me work. So in the case for Taiwan Semi, they have obviously hundreds of suppliers, and each time you approve a supplier, there’s a significant amount of cost that’s involved.

You have to trial and test their products. You have to make sure that these products are actually yielding. You have to make sure that you trust these guys, and you have to make sure that you can see that they can develop with your roadmap. So that means that, on the flip side, if you want to be cost-effective as a Taiwan Semi, you probably don’t want to have too many suppliers. Because if you do that, you have to keep on approving all of these suppliers all the time. You have to share your roadmap with all of them, and you have to do R&D with all of them. So actually, for you, within reason, you don’t want to have one supplier, obviously. Within reason, it makes sense for you to consolidate your suppliers.

So if I’m Entegris, I’m just picking numbers here, right? If I can sell them 10 chemicals versus five, that’s really beneficial for them because that means they can come to me with their problems for 10 chemicals, which means that they have significant cost synergies and also revenue synergies actually, because that means they’re derisking their business. So that’s what I mean with “one throat to choke.”

And, Entegris has been … I believe CEO Bertrand Loy has been the architect of that with his entire team. I think he’s seen that. So he said, look, let me combine chemicals, filters, some semi capex equipment stuff such as wafer handling, let me put this all into one piece because there are synergies between them. And then Taiwan Semi is basically going to have my throat to choke, but I think I’m the right throat to choke because I know what I’m doing.

Kevin Murphy: Another thing you point out in some of the papers you’ve written is that Entegris products are usually “specked in to” [written into the specifications of]. Explain that, is that the design of the microchip, or is it the design of the fabrication facility broadly?

Daniel Pilling: Yea, so the way this works is that there’s a roadmap, and I think semis probably have one of the longest roadmaps out there. You have literally a 10-year roadmap of what’s the transistor going to look like—what are we hoping to achieve effectively. And Taiwan Semi and Samsung and Intel—the leading-edge fabs in the world—drive that bus. And then they need a lot of partners. So when they say, for example, at two nanometer, I want to do something called “a gate-all-around.” And that means that there are certain things I need to do to the transistor, and that requires a certain type of filtration and a certain type of chemical. They will go to Entegris and will tell them these are the things I require, and this is the timing of when I will require them.

Can you do this, and can you deliver in this moment in time? And Entegris will … there’s an R&D-intensive business. I’m not sure what they will say on this particular point, but most often I would assume they would say, yes, we can do this. This is the research that we’ve done. This is a timeframe we can deliver. And you get effectively designed into the process. So at two nanometer or whatever node, Entegris will know, OK, these are the chemicals that are required. These are the filters that are required. I am designed into here, here, here, and here. That’s the R&D I need to do, and these are the facilities I need to build.

And maybe to give you an example, the company just went through the biggest capex investment cycle ever in the past three years. A cynic may argue that the working-from-home environment has probably helped, but actually there’s also some real demand here. So the real demand is they build a huge facility in Taiwan, right next to TSMC [Taiwan Semiconductor], and it goes back to your question. So they know they’ve been designed into their process for the next three, four, or five years, and there’s going to be a lot of capacity requirements. So they’re prebuilding for that capacity requirement. And then the nice thing here is that, basically – there’s a nice side effect – so when you’re a Taiwan Semiconductor, it takes you a long time to trust someone.

Entegris is one of the few trusted sources that can do that because— guess what? If in three years, two nanometer happens, and Entegris doesn’t deliver, two nanometers is not going to happen. And even the biggest guys in the industry—NVIDIA—just can’t get their chips. So this is really important, and it’s a very trusting position. That’s what I meant in those notes. When you say you get designed, and it’s like a cool process of here’s a roadmap, please do the R&D and deliver these chemicals. Can you do it? If so, let’s do it together.

Kevin Murphy: So that sounds like very high, almost impossibly high switching costs for the fabs. Difficult for a new entrant to come into the market without a long, long lead time.

Daniel Pilling: Yes, I would agree. And from that perspective, Entegris fits our criteria really well. The switching cost here is, frankly, gigantic. And we can think through it like this. One, chemicals and filters are a fairly small part of the overall cost here. I mean, I’m not going to give a percentage because I don’t know the exact percentage. But I can give you one number, the ASML photolithography equipment—one machine can cost hundreds of millions of euros. This is not even close. So it’s a fairly small part of your total pie. And now, if you were to take a risk on that, maybe your savings wouldn’t be that significant. But the risk is basically that you can’t manufacture. Another example, if you look at Entegris specifically, it turns out there are only two companies in the world really that can manufacture leading-edge filters. There’s Entegris, and then there’s a business called Pall, which is owned by Danaher. Entegris has by far the largest market share. There are only two, and you get designed in three or four years in advance. So even if you wanted to, it’s kind of hard to get a second source. So all that leads to your point: It’s very difficult to replace these guys once you’re designed in.

Kevin Murphy: Yes. So you brought up ASML and photolithography, and that’s a capex expense. And I think you’re comparing apples to apples when you look at the capex from Entegris, but there’s another component that is equally compelling for Entegris, which is the consumables business. Can you describe that and why that’s an advantage for them?

Daniel Pilling: Yes. I just want to be clear I think this entire space is great, whether it’s capex or consumables. And we’re broadly invested in all of them. Now there is a nice unique element about Entegris, given the consumables nature of it. Because capex naturally is a bit lumpier because nobody knows really what the end demand is within a year, so that means that maybe you buy a bit too much capex, which then means the next year you may digest it. So it’s quite lumpy and cyclical at times.

Now, for consumables, that applies much less so. Because each time you manufacture a chip, you know for sure that chip’s going to consume chemicals and it’s going to consume filters, and it’s a bit more stable from that perspective. So Entegris is very unique as a company in that view because, at least, I don’t know of any other consumable type of company that is focused on the semiconductor industry with this type of high-quality product. So it’s a pretty unique position.

Kevin Murphy: That’s interesting. I think it might also be kind of interesting to hear your perspective. Well, let me back up. You talked about leading-edge chips, and there’s a lot of growth in that. The training chips on the GPU side, for sure, are some of the most sophisticated chips out there. But I had read somewhere that beyond AI … Looking at, say, autonomous driving or any new car coming off the line that’s an EV [electric vehicle] with the potential for autonomous driving—the number of trailing-edge chips in those cars is growing faster than the number of leading-edge chips. Does Entegris have a spot in that business as well?

Daniel Pilling: For sure. The chips you’re referring to are generally called analog chips.

Kevin Murphy: Yes. Somebody described it as the chips that make the windows go up and down versus the chips that make the car stay on the road.

Daniel Pilling: Yes, actually, there are multiple. There are chips that make the windows up and go down. Those are trailing-edge chips, [also known as] logic chips. But then there are also chips that let the car see and sense their environment, which are called analog chips. And then there’s a third subsegment, which is basically the computing brain of a car, which is obviously going to be very significant in a self-driving car, right? Because it’s like a human brain basically needs to then decide how to drive, so you have three things. And in all of those, Entegris will play a role. Because all of those, again, require chemicals and filters to be manufactured. And for Entegris, though, all three are helpful, whether it’s the leading edge or the trailing edge. But you sell more chemicals and filters on the leading edge, which we’ll probably get to later too. I can talk more about that.

Kevin Murphy: Sure, actually why don’t we talk about that now? Give us an idea of what you mean by that and why that’s the case.

Daniel Pilling: Yea sure, so high level, you can think about Entegris like this. I think we have 30 years of data for so-called wafer growth. Wafer growth is just another measure of the actual, how many more chips are we selling physically each year. So we’re completely ignoring Moore’s Law and all that stuff.

We’re just saying how much more silicon is out there each year. And that’s about 5 percent each year for a long time. And it goes back to your point in the beginning that anything has a chip inside now. And each year, there are more things with chips inside. There has been a 30-year trend. So I think we can say that probably continues. That’s about 5 percent growth each year—5 percent or 6 percent.

Now then you say, well, OK, so Entegris on the leading edge, as we discussed a bit before, too. Each time you put out a new leading-edge chip, it’s like building a bigger skyscraper effectively, and it’s becoming much, much more sophisticated. When you build a bigger skyscraper, you need more cement, more metal, more sophisticated materials. It’s the same here. When you go to the leading edge, you’re going to need more chemicals, more filters, more process steps. So for Entegris, that’s great. That means they can sell much more of the materials as the Taiwan Semis of the world go from five-nanometer to three-nanometer to two-nanometer chips.

Now, if we put this into numbers, we can take the 5 percent wafer growth, and then we say, well, Entegris as a business probably outgrows this industry by a few percentage points. So in the past, its growth has been somewhere between 3, 4, or 5 percent. You could hope that it’s bigger than that in the future. But, in general, you would think that they can outgrow this. And again, this is a laws-of-physics type of thing. I mean, it’s hard to argue against that. So that’s what I mean when I say the leading edge, they can sell more stuff because they’re just building more complex things that require more filters and chemicals, and there’s no way around that.

Kevin Murphy: All right, let’s shift gears a little bit to the end market too, which is, I think, another strength of this business. There are clearly market share leaders in different segments of the chip end market. Intel, back in the day, clearly a leader. NVIDIA today in GPUs. AMD picking up some share as well from that. Is it fair to say that in owning a company like Entegris, you’re not necessarily making a bet on who wins at the end of the day in terms of the brand of chip because they’re a kind of an “arms dealer” to the industry broadly?

Daniel Pilling: Absolutely, Kevin. I think you can make this argument for Entegris. I think you can equally make this argument about any other semi capex company we own, such as ASML, Lam Research, etc. And you can make that argument also about Taiwan Semiconductor. And maybe to deepen the point a little bit, there are going to be multiple drivers, which is unique and has never happened before in the semiconductor industry. The big one today is machine learning. We’re super excited about that, and we can talk about that. But there are others too. You pointed out the fact that self-driving cars – going to need a lot of sensors for that. There’s going to be IoT [Internet of Things] chips and everything they can see, sense, and think.

There’s the metaverse. I know nobody talks about it anymore, but I thought the presentation of Apple Vision [Apple’s Vision Pro augmented reality headset] was pretty amazing. So maybe there’s something there too. And all those things will need chips. So basically, the companies at the manufacturing layer, they will all benefit, right? Which is the foundry layer, the semi capex layer, and the consumables layer. And they will benefit no matter what. If the metaverse is the next big thing, they will benefit. If AI is the big thing, which probably is, they will benefit too. If it’s AMD or NVIDIA—and we have a strong view that it’s actually NVIDIA, right?—But if it’s AMD, they will win too. So I agree with your thinking.

Kevin Murphy: So that’s kind of our history—not just in this industry, but in others—at Sands Capital in finding not only the chokepoint but the platform, the arms dealer, the business that is critical no matter who the end-product winner is—and it sounds like it’s that kind of company.

Daniel Pilling: So for Entegris, just from a physics and manufacturing perspective, it matters very little where something gets manufactured, right? I mean, you’ll still need chemicals, you’ll still need filters. Now you could argue that if you manufacture the stuff elsewhere, maybe in Arizona, in the U.S., that, at least initially, the yields will be worse, which then means you’re going to throw away more chips, which means you may need more chemicals. Now, in the long run, that’s not a great business investment case, right? And we’re certainly not hanging our hat on that at all. In the long run, frankly, also, I think the CHIPS Act is interesting, and it’s important for the world to have more supply in different places in the world; it’s super important. But ultimately, what drives the bus here is not that. What drives the bus is that you, me, and everyone else, in two years, we’re going to buy a new smartphone because it has new applications.

In two years, we’re going to have a much bigger footprint in the cloud—each single person. Yeah. Because there are going to be recommendation engines at Netflix running Kevin’s preferences. And they’ll try to monetize that. There’ll be some sort of AI that mirrors your preferences on Amazon, etc. So your semiconductor footprint is going to go up tremendously. And somewhere in the world, somebody’s going to manufacture that. And Entegris and many of the other companies that we own will all benefit from that. That ultimately drives the bus.

Kevin Murphy: That’s great. Maybe give us the general picture on why Entegris, in your mind, is a quintessential Sands Capital investment broadly and then, maybe more specifically, a quintessential technology investment.

Daniel Pilling: Yes. There are a few things I’d highlight. First of all, at Sands Capital, we like companies that have unique prominent cultures and leaders. And I think Entegris really falls into that, in my opinion. I followed this business for about 10 years or more. And Bertrand Loy, the current CEO, has been the CEO since 2012. And I think when he took the helm, a few things happened. First of all, I think he saw the opportunity that we’re seeing today, too, right? You combine a product portfolio and make it easier for Taiwan Semi to choose you because you’re doing it all. That’s very unique and has very long legs. I think the second thing that happened is that they have become an employer of choice for the chemicals and filtration space, which turns out is probably not the biggest industry in the world if you’re supplying to semiconductors.

So if you’re doing a Ph.D. in this field, Entegris will probably know your professor. You will naturally go there. If you’re studying this stuff, Entegris will be close to you. If you want to do your life’s work, they’re probably your employer of choice. And that’s interesting, too, right? So they’re sucking up all the good talent in this industry. They have a great culture and a great ability to attract great people.

And then the second thing is obviously the competitive moat and competitive differentiation. And I think that goes back to one thing we discussed in the beginning. The R&D intensity to do these things is going up tremendously because we’re shrinking the transistors, the chemicals are becoming more sophisticated, and the filtration requirements are going up.

That naturally leads to one company leading because the R&D dollars are going up, and you can’t have two, three, four, or five companies all replicating that at the same time because it wouldn’t be profitable. So Entegris has significant competitive advantages stemming from R&D intensity, hiring the right people, being designed in the long run, and being trusted by their partners. So there’s a significant competitive advantage too.

And lastly, if you think about the growth here, I mean, I kind of gave you the base case, but let’s think about maybe more than the base case. The base case was—just to remind everyone—is like 5 percent wafer growth, leading edge growing, and you need more chemicals on the front, which means like maybe you get all in like 9 percent or 10 percent growth.

Now let’s think about AI and let’s think about the big explosion in use cases there. AI is very, very, very semiconductor intensive. To train these models is very intensive. As we’ve seen with NVIDIA, to run the inference is very intensive. So maybe there’s a case to be made that the demand for compute actually accelerates in the next few years, right? Because you have AI, maybe you have self-driving cars, you have IoT, you have maybe the metaverse at some point, right? So if that happens, if it accelerates, that means you’re going to need more chips on the leading edge, which means that your growth could be much better than 10 percent, potentially—even 10 percent would be a great outcome.

And then maybe last point, if you look to the last one of our criteria, is obviously valuation. And if you think about this company, I mean, we can, even if we just take 10% growth, it will trade at a very, very, very attractive valuation five years out.

So then you say you have a consumable company growing at 10% for a long time trading at such an attractive valuation. That’s probably a very good outcome. So I think it’s a great fit for all our criteria based on those metrics.

Kevin Murphy: Yeah, that’s great. You gave a great answer yesterday when we were talking about how [NVIDIA CEO] Jensen Huang said that this is an iPhone moment, and you took exception to that. So to your point about the end buyer as a person of the iPhone. There are only so many people out there, so you can only sell so many iPhones. But in the case of semiconductors broadly—and GPUs, maybe more specifically—the end buyer is a corporation. It’s an industry that wants to either improve their client experience or whatever. Explain that a little bit more.

Daniel Pilling: Absolutely, Kevin, so one thing I think that’s interesting to look at is sort of the ERP, the enterprise resource planning implementations of the late nineties and the 2000s. I think one big thing we can believe about most human beings is that most do not want to do an ERP implementation. It’s painful. It takes years. You have to run big teams, and everybody’s like, “I don’t want to do that.” But then, if you look at why they did it, it is because if you don’t do it, and let’s say you have an industry with five players and the other four players do it, you’re probably going to be out of business in 10 years.

That’s a really nice selling point. So you go do it. So the same thing is happening here now. Where you say, well, OK, so how do we improve productivity? It looks like one big way is machine learning and AI, like ChatGPT, is showing that left, right, and center. So every company in the world is going to have to implement this one way or the other because their competitors are doing it.

It doesn’t matter what macroenvironment we’re in. It doesn’t matter whether we are in a booming economy or in a hard landing. It doesn’t matter. You’re going to have to do this. And that’s really nice because you used to sell, and you’re still selling, but your biggest use case was smartphones. So if Apple doubles the price tomorrow, I’m not going to buy a smartphone because I’m budget constrained as most people are. Right. So I just can’t do it. But with the corporations, if AI is so important that basically you have to do it or you go out of business or you lose market share, let’s say in 10 years, you’re going to do it, and you have a lot of dollars to do it.

So basically, the person you’re selling to is moving from a budget-constrained consumer to a very deep-pocketed big company. And that’s really nice because that means you can go a long way selling this thing, and it’s going to be really beneficial too. And then, if you compare and contrast the market sizes, right, I would bet that the AI market is probably going to be much bigger than a smartphone market. But I don’t know. Frankly, it doesn’t matter as long as it’s going to be very big.

Kevin Murphy: Yes, so it’s a good case for continued strong growth in the semiconductor space broadly. I think when you put a five- to 10-year lens around an investment case, you always have to ask, what’s the tailwind that will continue this secular trend of the future? And I think that’s a really good example of that. And you mentioned something earlier, too, that AI is here to stay for a while. But it’ll fade at some point. And you don’t know what it is, but there will be another thing that will surprise us in the kind of evolution of the demand cycle within semiconductors, and I think that’s a pretty powerful point.

Daniel Pilling: Frankly, It’s probably going to be a long time before AI fades, right? I mean, I don’t know, but it feels like it’s a long time. I think the nice thing to understand is that when AI scales, it’ll naturally bring some sort of other use cases with it. For example, the big use case might be self-driving cars. That’s an AI use case. And whenever that happens, we’re going to need a lot of chips to do that. Similarly, for the metaverse, a big problem is that the display technology is so expensive because we need way more pixels. Now, maybe AI will help you to design a display at a lower cost, and maybe AI will enable the metaverse. And that will be great because that again, it is probably a cool experience for a consumer, but also means many more chips. So to your point, we don’t know exactly how this plays out, but if you look at the history of the transistor and the history of Moore’s law and improvements of compute, it seems like these use cases just pop up, right?

I don’t think anybody foresaw the PC. I don’t think anybody saw the smartphone. I don’t think anybody saw ChatGPT, really, but these things just happen because you’re on this path of improvement. And I bet we’re going to see really cool things over the next three, four, or five years that will mean multiple other growth factors that we’re not even implementing today.

Kevin Murphy: OK. I think that’s helpful to walk us through that framework there. What specifically on Entegris or generally on the industry do you want to leave us with?

Daniel Pilling: I’m of the opinion that we’re in a very special moment in time for this industry. It took 30 years for this industry to consolidate. And, as mentioned, it consolidated because R&D intensity went through the roof. In this position now, we have oligopolies, monopolies, and each little Lego brick is required to get to the end product. That’s an interesting place to be.

The second thing that seems to be happening is that you really have an acceleration in demand. Demand used to be a function of how many people do you have in the world, right? And there’s a lot of people, but it’s still finite. Now the demand is going to AI, machine learning, IoT, just data. And I would argue, I mean, it’s probably finite too, but much less finite than people. And then you say, this is the new driver for compute. That probably means that the need for compute goes up. So then you have this, again, this supply structure of a pretty consolidated industry with an accelerating trend or need for compute.

And then you wrap this around, for example, what I said about Entegris, right? Dominant, great culture, great valuation. So it looks like you have an opportunity to generate great returns for our clients in the long run here. And I would argue this opportunity exists for a few reasons. First of all, it’s a cyclical industry, so most people shy away from that. Second, it’s a trading industry, so most stocks are being traded in this industry on a quarter-to-quarter basis, not on a five-year basis. And third, I think there are still some doubts out there in terms of the duration of the growth here. So all of those things hopefully enable us to own these companies in the long run at big weights and generate hopefully great returns for our clients.

Kevin Murphy: Excellent. That’s the growth investor’s optimistic mindset. I like hearing that. Thanks, Daniel. That was really interesting. As I said, I could, I could have this conversation with you for hours, but I think I think we covered a lot of ground here. So we’ll wrap it up on that point.

Daniel Pilling: Oh, thank you, Kevin. I can talk about this for hours too. So that makes two of us.

Disclosures:

The views and opinions expressed herein are those of individuals and may differ from the views and opinions expressed by Sands Capital. The views expressed are current as of the episode date, and are subject to change. This material may contain forward-looking statements, which are subject to uncertainties outside of Sands Capital’s control. The securities identified do not represent all of the securities purchased or recommended for advisory clients. There is no assurance that any securities discussed will remain in the portfolio. You should not assume that any investment is or will be profitable. A company’s fundamentals or earnings growth is no guarantee that its share price will increase. For more information, including a full list of portfolio holdings, please visit our website at www.sandscapital.com.

As of November 30, 2024, Entegris, ASML, Taiwan Semiconductor, NVIDIA, Lam Research and Samsung were held across Sands Capital strategies.